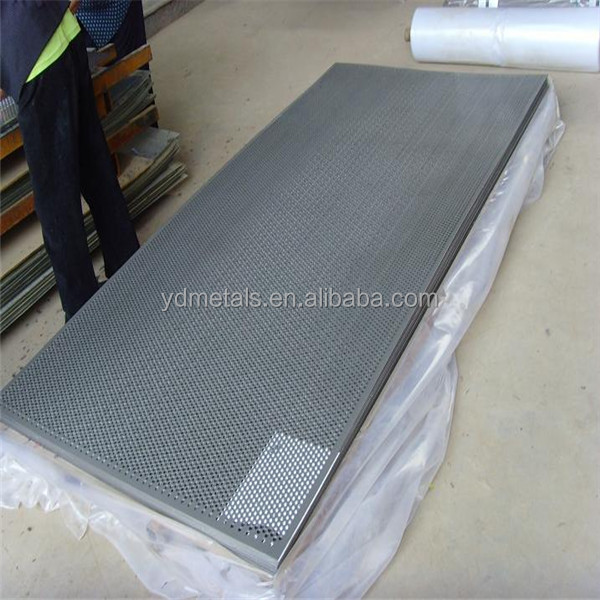

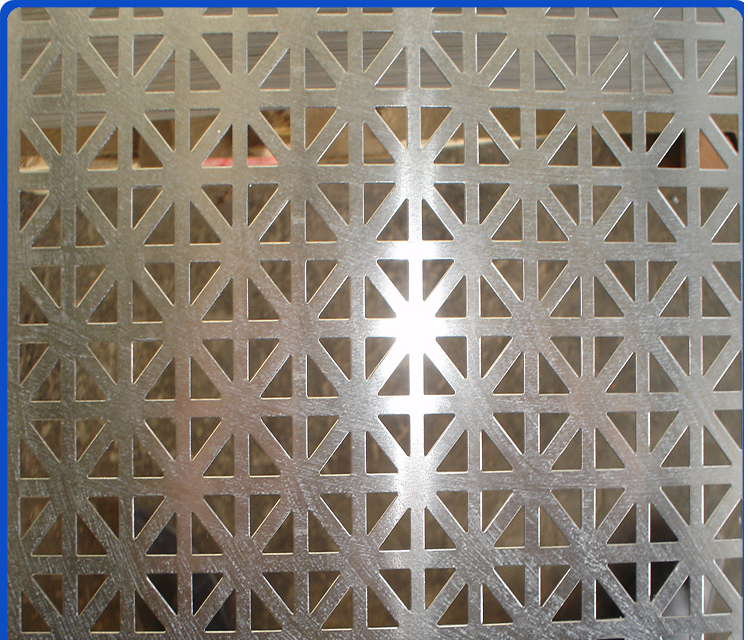

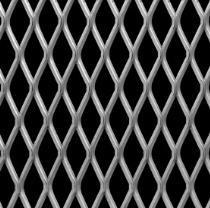

Logam berlubang nawiskeun solusi anu serbaguna pikeun perusahaan di seueur industri. Produk lambar logam perforated didamel nganggo panggunaan punches atanapi presss anu ngahasilkeun slot, palang, liang atanapi pola anu sanés dina logam. Perforasi tiasa dilakukeun pikeun tujuan fungsional, sapertos ngajantenkeun produk langkung adaptasi sareng sarat kinerja pabrikan, atanapi pikeun ningkatkeun pidangan produk anu parantos réngsé. Logam perforasi kami serbaguna sareng fungsional dina sadaya aplikasi arsitektur. Staf anu berpengetahuan kami tiasa nganggo cetak biru anjeun pikeun nyetak cetak pikeun ngabantosan proyek anjeun.

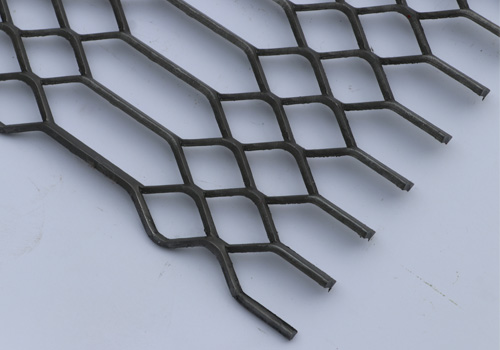

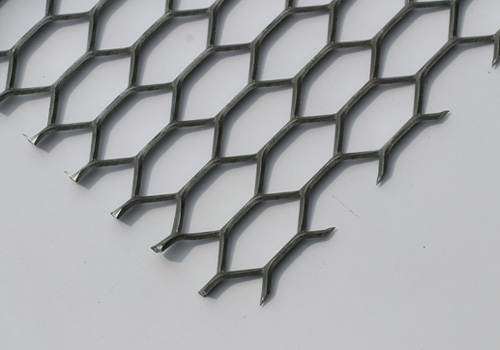

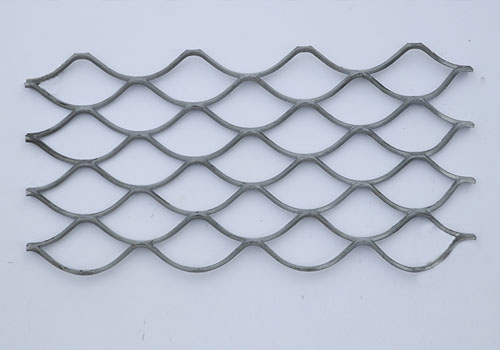

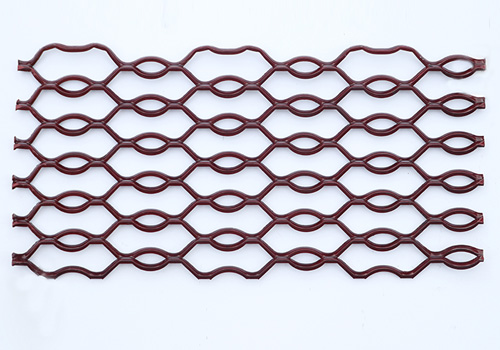

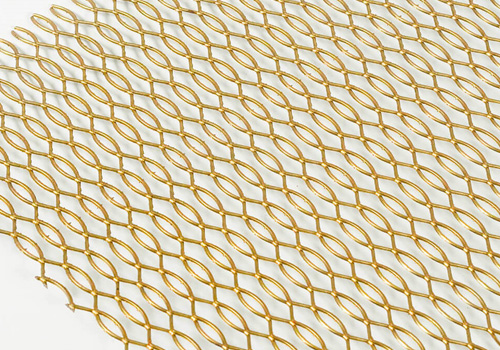

POLA LUAS PISAN LARIS

E062 / 125 22% daérah gratis

E062 / 125 22% daérah gratis E078 / 137 29% daérah gratis

E078 / 137 29% daérah gratis E093 / 157 32% daérah bébas

E093 / 157 32% daérah bébas E093 / 250 Daérah bébas 13%

E093 / 250 Daérah bébas 13% E098 / 157 35% daérah bébas

E098 / 157 35% daérah bébas E118 / 196 Daérah bébas 33%

E118 / 196 Daérah bébas 33% E125 / 250 Daérah bébas 23%

E125 / 250 Daérah bébas 23% E125 / 250 Daérah bébas 23%

E125 / 250 Daérah bébas 23% E157 / 187 aréa bébas 64%

E157 / 187 aréa bébas 64% E157 / 250 36% daérah gratis

E157 / 250 36% daérah gratis E187 / 250 Daérah bébas 51%

E187 / 250 Daérah bébas 51% E196 / 275 46% daérah gratis

E196 / 275 46% daérah gratisformat-Ukuran mm 1000 × 2000

| Liang | o / a | waja karbon | stainless steel SS304 | aluminium | waja galvanis | ||||||||||||||||

| Kandel | |||||||||||||||||||||

| R | T | % | 1 | 1.5 | 2 | 3 | 0.4 | 0,5 | 0,8 | 1 | 1.5 | 2 | 3 | 1 | 1.5 | 2 | 0,5 | 0,8 | 1 | 1.5 | 2 |

| 0.4 | 1.5 | 6% | ● | ||||||||||||||||||

| 0,5 | 1.5 | 10% | ● | ||||||||||||||||||

| 0.6 | 1.5 | 15% | ● | ||||||||||||||||||

| 0,8 | 1.8 | 19% | ● | ● | |||||||||||||||||

| 0,8 | 2 | 15% | ● | ||||||||||||||||||

| 1 | 2 | 23% | ● | ● | ● | ● | ● | ||||||||||||||

| 1 | 2.2 | 19% | ● | ||||||||||||||||||

| 1.5 | 2.5 | 33% | ● | ● | ● | ● | |||||||||||||||

| 1.5 | 3 | 23% | ● | ● | ● | ||||||||||||||||

| 2 | 3.5 | 30% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2 | 3.6 | 28% | ● | ||||||||||||||||||

| 2 | 4 | 23% | ● | ● | ● | ||||||||||||||||

| 2 | 4.5 | 18% | |||||||||||||||||||

| 3 | 5 | 33% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 3 | 6 | 23% | ● | ● | |||||||||||||||||

| 4 | 6 | 40% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| 4 | 7 | 30% | ● | ● | ● | ||||||||||||||||

| 5 | 7 | 46% | |||||||||||||||||||

| 5 | 8 | 35% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 6 | 9 | 40% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| 8 | 12 | 40% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| 10 | 15 | 40% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

Urang Sunda = diameter buleud liang

T = pitch liang, ngahalangan dina 60%

APLIKASI

- Bangku luar sareng pedalaman

- Karanjang sareng tong sampah

- Layar sareng kendang

- Unsur arsitéktur

- Ékstrak lebu

- Saringan hawa sareng minyak

- Mufflers sareng pipa knalpot

- Jati kebon

- Panél siling palsu

- Layar pikeun lampu

- Radio sareng radar

- Kulkas

- Hawu ventilasi

- Gandum garing sareng sortir

- Sistem akustik

- Crushers buah

Alesan luhur pikeun milih

- Penampilan anu pikaresepeun sareng umur jasa anu panjang.

- Penampilan anu pikaresepeun sareng umur jasa anu panjang.

- Bahan anu berventilasi sareng napas.

- Alami hampang sareng gampang digarap.

- Épék ngarugikeun sora seragam.

- Non-magnét, anti korosi.

- Rupa-rupa ukuran liang, bentuk, pola anu sayogi.

- Kandel plat aluminium opsional.